How To Remove Oil From Refrigeration System

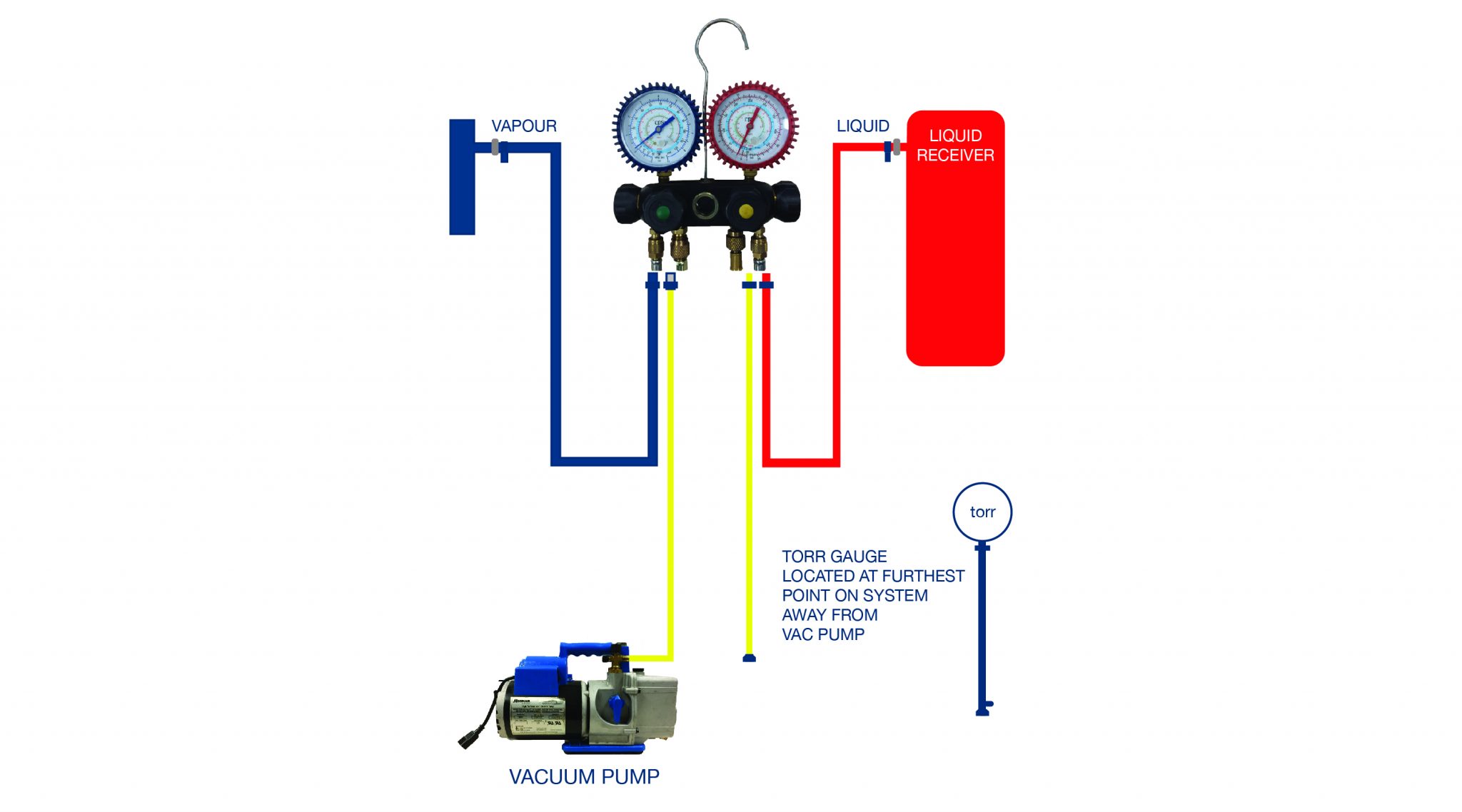

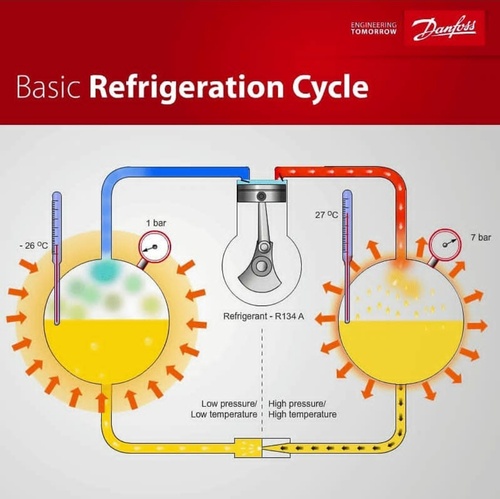

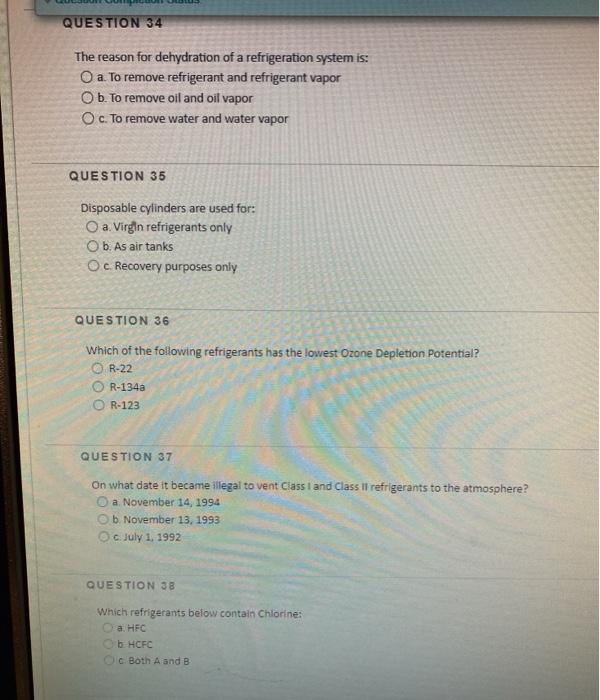

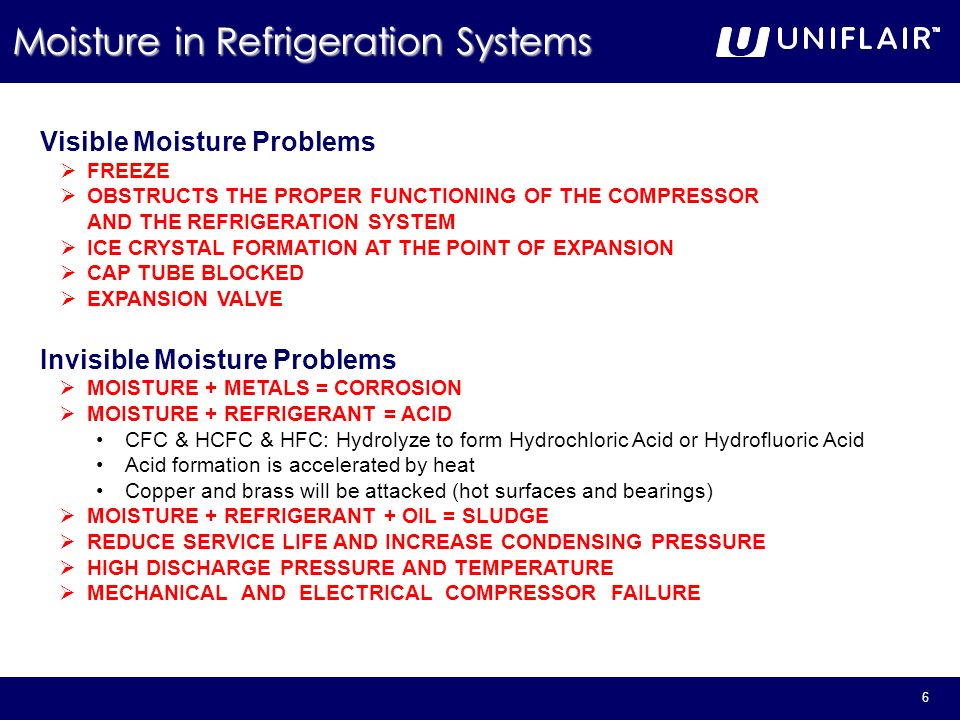

How to remove oil from refrigeration system. MAINTENANCE FEE REMINDER MAILED ORIGINAL EVENT CODE. The evacuation process is the next step in which the vacuum pump is used to remove the air and moisture from the refrigerant system. Connect the collecting cylinder to the purging line of the condenser open the valve and collect air in the cylinder.

Keep a log of the quantity of refrigerant oil drained and the amount that is added to the system. This requires an airtight container or preferably a graduated cylinder so that the number of oil removed can be measured and the exact amount replace. But in the case of R-134a the refrigerant effectively competes with the ester lubricant in partitioning the water ie the water moves from the lubricant to the refrigerant.

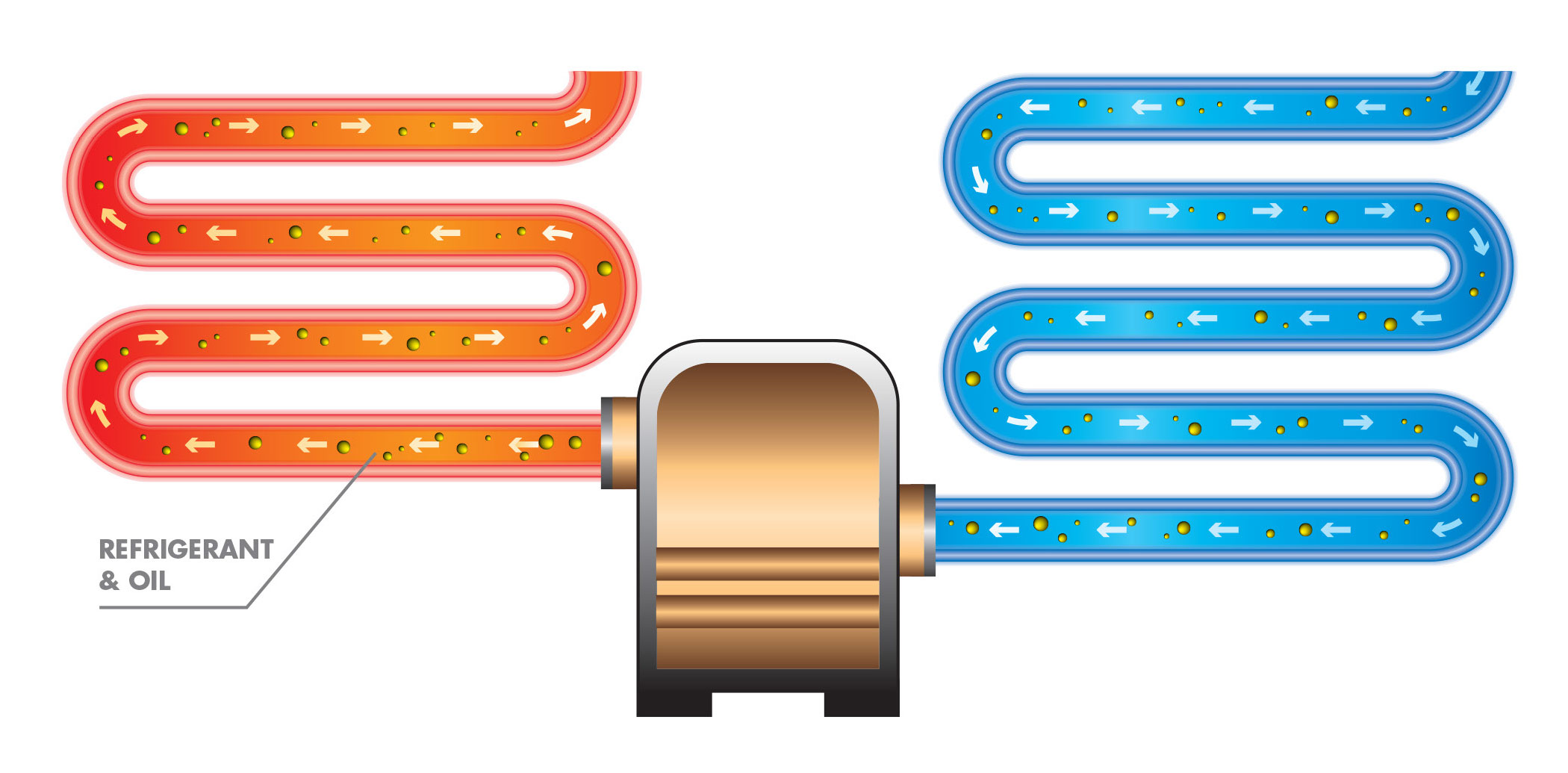

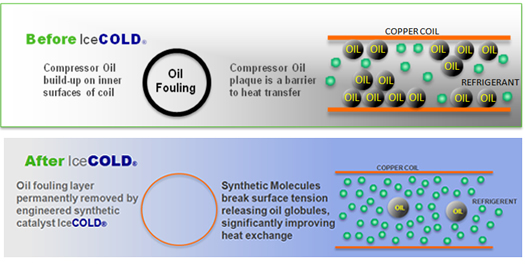

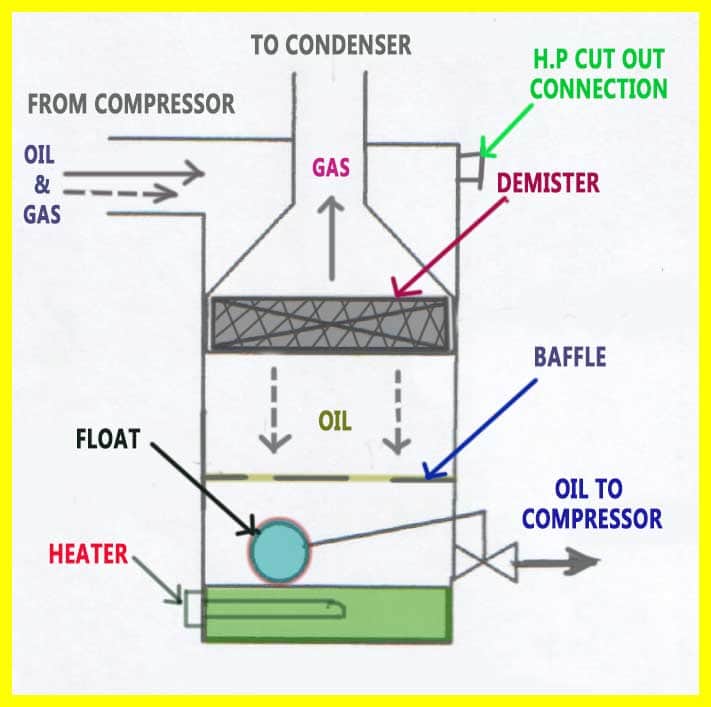

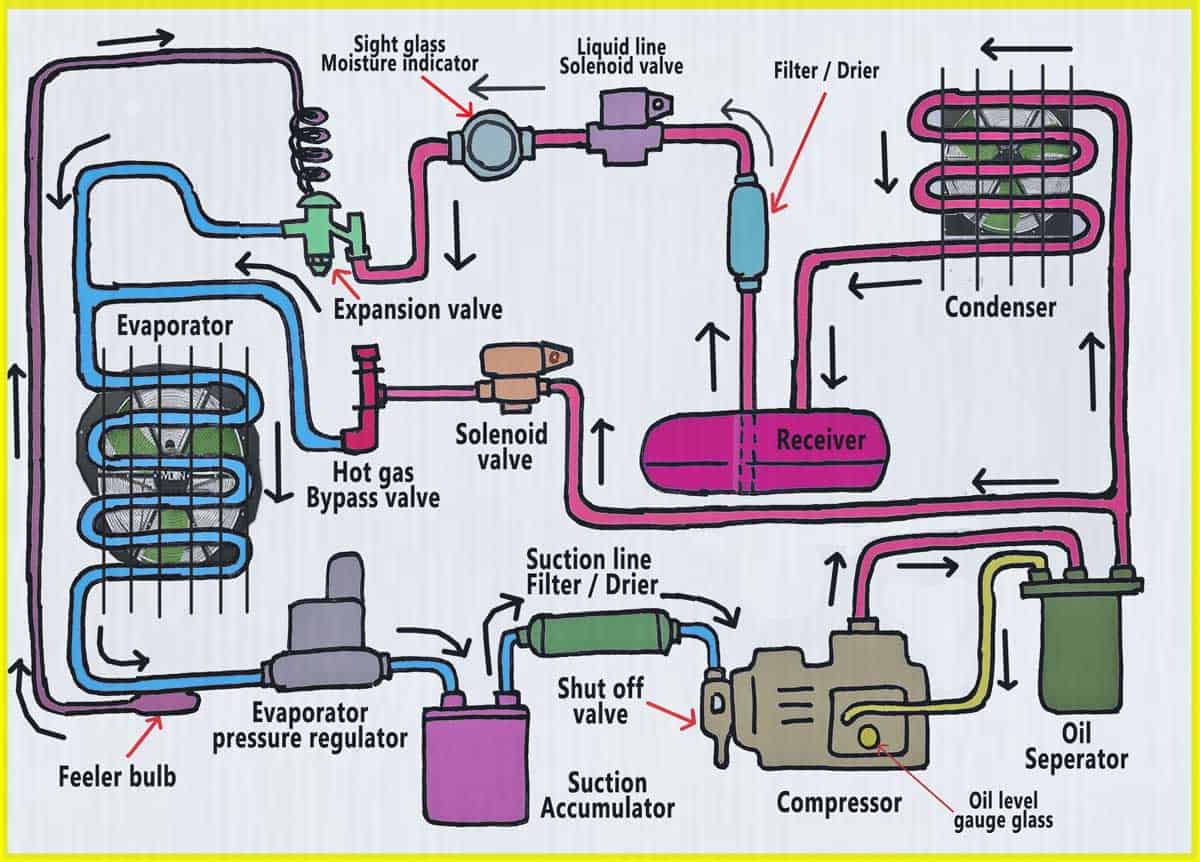

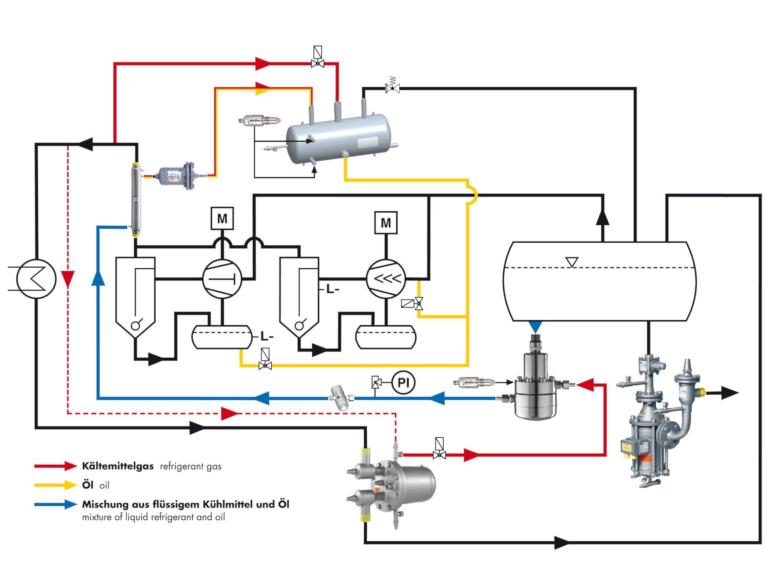

Oil separators are used to remove and filter out this oil from the mixture to improve the performance of the system. Prepare written procedures for the draining and addition of oil and post them in the machinery room. Remedies for Air in Refrigeration Plan.

Similarly what effect does moisture have on a. This helps eliminate the risk of opening the system to the atmosphere and potentially pouring liquid refrigerant into an enclosed space the engine room or the refrigerated space. We fill in this way 20 l in - 20 minutes.

Thanks for watchingGuy Browns Youtube Channel was launched to bring together fa. Starting the compressor pumping the gas in the low-pressure system to the condenser or high-pressure reservoir. The pressure-temperature relationship becomes impaired.

Pump the entire gas into the condenser by running compressor. New oil will speed up the evacuation process. Pulling a vacuum container or cylinder the oil will be removed from the compressor in the cylinder Fig.

Excess oil may accumulate in the evaporator and then return to the compressor in a slug. Chiller oil should never be removed directly from the refrigeration system or from the high-pressure receiver.

While circulating it can come in contact with other contaminants such as moisture and form an acidic sludge that can do serious damage.

The evacuation process is the next step in which the vacuum pump is used to remove the air and moisture from the refrigerant system. POEs hold moisture more tightly than mineral oil. Excess oil may accumulate in the evaporator and then return to the compressor in a slug. This requires an airtight container or preferably a graduated cylinder so that the number of oil removed can be measured and the exact amount replace. Industrial Refrigerated Systems is a Berg Company. Remedies for Air in Refrigeration Plan. But in the case of R-134a the refrigerant effectively competes with the ester lubricant in partitioning the water ie the water moves from the lubricant to the refrigerant. Thanks for watchingGuy Browns Youtube Channel was launched to bring together fa. I show how to remove compressor oil with a vacuum pump.

Prepare written procedures for the draining and addition of oil and post them in the machinery room. How to Eliminate the Worst Refrigerant Contaminants. The problem was excess oil on the refrigerant side of the chiller. In sufficient quantities Mark Key. Small 1 - With the new compressor installed turn on the compressor and depress the access valve. If thats the case after isolating the compressor remove the drain plug and install the correct fitting. But in the case of R-134a the refrigerant effectively competes with the ester lubricant in partitioning the water ie the water moves from the lubricant to the refrigerant.

Post a Comment for "How To Remove Oil From Refrigeration System"